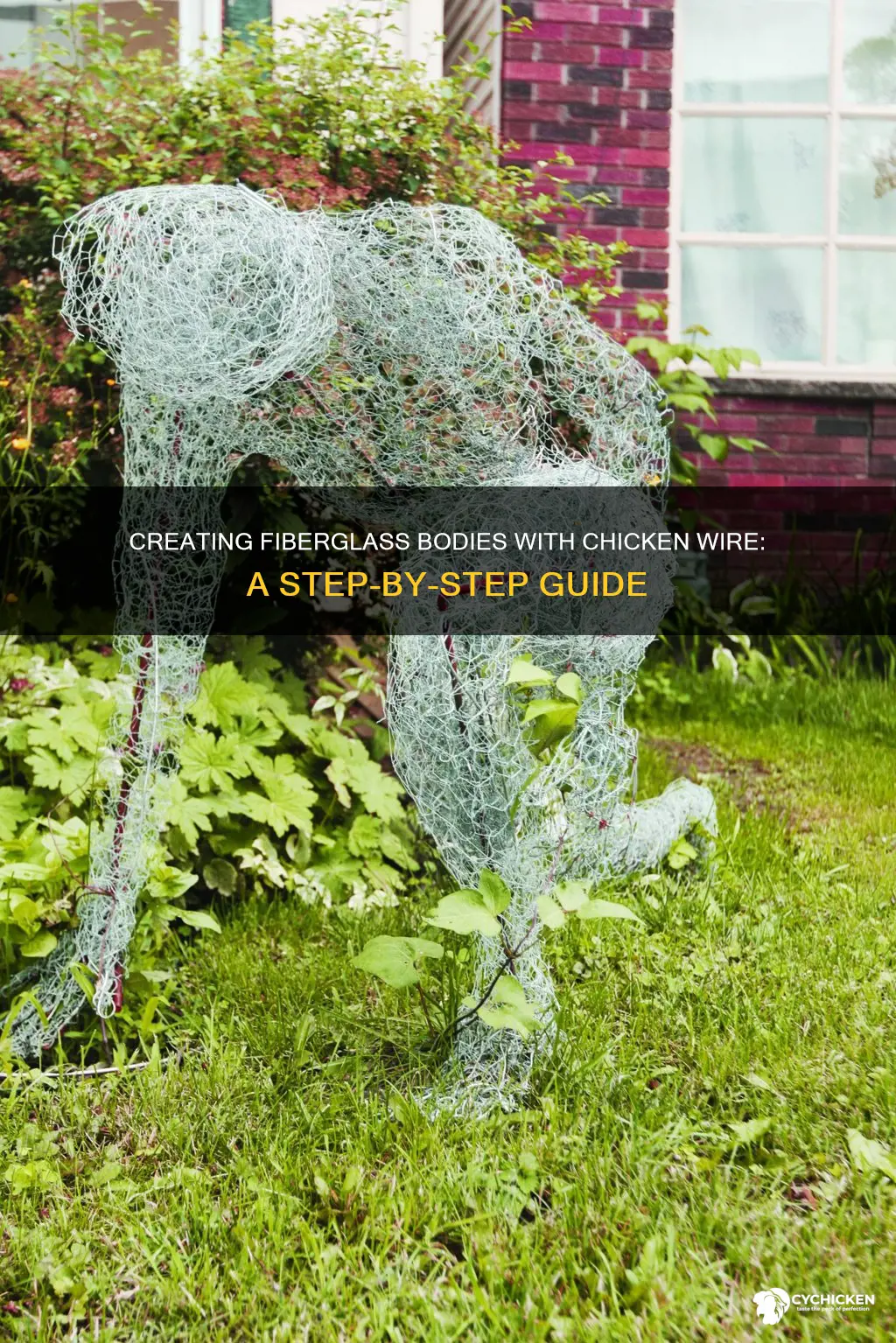

Creating a fiberglass body with chicken wire is a great way to make large fiberglass pieces or sculptures. Chicken wire is a positive mold that can be used to shape fiberglass, which is typically done using a negative mold. This process involves creating the desired shape out of chicken wire, covering it with aluminum foil, and then draping fiberglass mats dipped in resin over the structure. Multiple layers of fiberglass are built up, and the original chicken wire sculpture is discarded once the fiberglass has hardened. This method is simple and effective, making it a popular choice for projects such as home-built campers and wooden boats. It is also a good option for bodywork as it is light, see-through, and capable of keeping light debris out.

| Characteristics | Values |

|---|---|

| Materials | Chicken wire, fiberglass mats, resin solution, aluminum foil, mold release agent, epoxy, polyester resin |

| Process | Create desired shape with chicken wire, cover with aluminum foil, spray with mold release agent, dip fiberglass mats in resin solution and lay over sculpture, let dry, add additional layers of fiberglass and resin as needed |

| Advantages | Lightweight, easy to see through, can keep light debris out |

| Considerations | Ensure smooth surface with minimal lumps, clean up spilled resin with turpentine, wear protective gear when handling resin |

What You'll Learn

Create a chicken wire mould

Creating a mould using chicken wire is a great way to shape and manipulate materials like fiberglass. Here is a step-by-step guide on how to create a chicken wire mould:

Step 1: Create a Basic Shape

Begin by forming a basic shape with the chicken wire. You can do this by wrapping the wire around an object or person to achieve the desired silhouette. For example, you can start with a simple cone shape by wrapping the wire around a cone-shaped object. This will serve as the base for your mould.

Step 2: Build and Secure the Mould

Continue to add layers of chicken wire to build up the mould and achieve the desired shape. Secure the wire in place by twisting the joints together. You can use pliers or gloves to twist the wire without injuring your hands. If needed, use zip ties or wire cutters to help secure the connections and hold the mould together.

Step 3: Refine the Mould

Once the basic structure is in place, you can refine the details of your mould. Ensure that the design details are on the outside so that the final product will have the correct orientation. Smooth out any sharp edges or protrusions, and be cautious of any sharp wire ends.

Step 4: Prepare the Surface

After shaping the mould, cover it with aluminium foil. Smooth out any lumps or bumps that may cause issues during the casting process. Spray the entire sculpture with a mould release agent, which will aid in removing the final product from the mould.

Step 5: Finalize the Mould

Check that your chicken wire mould is secure and ready for the casting process. Ensure that all the connections are tight and that the mould can hold its shape. At this stage, you can make any last-minute adjustments or additions to the mould before proceeding with the fiberglass application.

Creating a chicken wire mould is a creative and versatile process that allows you to design and fabricate a wide range of objects. Remember to exercise caution when working with sharp wires and always wear protective gear, including gloves and safety goggles.

Tasty Chicken Treats: How Many Pieces in a Pound?

You may want to see also

Cover the mould with aluminium foil

When creating a fibreglass body with chicken wire, covering the mould with aluminium foil is a crucial step. This step ensures a smooth and seamless finish on your final product. Here's a detailed guide on how to cover the mould with aluminium foil effectively:

First, ensure that your chicken wire sculpture is securely shaped and that the wire is bent and fastened in place. This prevents any movement during the fibreglass casting process. Then, carefully cover the entire chicken wire frame with aluminium foil. It is important to do this smoothly and carefully, ensuring that there are no gaps left between the wire and the foil. Avoid creating lumps or bumps, as these will be challenging to sand down later in the process. The foil should be wrapped tightly around the wire frame, creating a smooth base for the fibreglass to adhere to.

Once the foil is in place, use a mould release agent to prepare for the fibreglass application. Spray the entire sculpture with the release agent, coating both the foil and the wire. This step will make it easier to remove the fibreglass from the mould later on. After the release agent has been applied, you can start the fibreglass application process. Cut your fibreglass mats to a manageable size that can easily be laid over the sculpture. Dip each mat into a resin solution, completely wetting the fibreglass. Then, lay the wet mat over the sculpture and press it into place, following the shape of the mould.

Repeat this process, layering the fibreglass mats until the entire sculpture is covered. Leave this initial layer to dry for several hours. By allowing the fibreglass to harden, you can then remove the mould and discard the chicken wire sculpture. Continue building up the layers of fibreglass until you achieve your desired thickness. Remember to let each layer dry thoroughly before adding the next one, and ensure that the fibreglass adheres well to itself for a strong and durable final product. Once you have completed the layering process, let the entire fibreglass cast dry overnight. Finally, clean up any spilled resin with turpentine, and don't forget to wear a particle respirator and safety goggles for your protection.

Smart Points for Chicken Shish Kebab: Counting Calories

You may want to see also

Prepare the fiberglass mats

To prepare the fiberglass mats for your chicken wire sculpture, start by cutting your mats into manageable sizes. The exact size will depend on the dimensions of your sculpture and how many mats you need to cover it. Once you have cut the mats to size, prepare a resin solution. Dip each mat into the resin solution, ensuring that the mat is completely wet and coated in the solution.

After coating the mats in resin, you can begin applying them to your sculpture. Lay the wet fiberglass mat over your chicken wire form, pressing it into place and moulding it to the shape. Repeat this process, applying mats all over your sculpture until it is entirely covered. Leave this first layer to dry for a few hours.

Once the first layer of fiberglass is dry, you can remove it from the chicken wire sculpture. This will leave you with a hardened fiberglass shell, and you can discard the chicken wire at this point. Prepare another batch of resin and lay down a new layer of fiberglass mat, ensuring that the layers stick together well.

Continue to build up the layers of fiberglass until you reach your desired thickness. Each layer should be left to dry before adding a new one. When you have finished building up the layers, leave the entire cast to dry overnight. Remember to wear protective gear, including a particle respirator and safety goggles, and clean up any spilled resin with turpentine.

Smart Eating: Chicken Caesar Wrap WW Points

You may want to see also

Layer the mats over the mould

To layer the mats over the mould, begin by cutting your fiberglass mats into manageable sizes that will easily fit over your chicken wire sculpture. You can use a chopped strand mat, which is the most popular option for mould-making as it builds thickness quickly and can be torn into pieces. Prepare the mats by dipping them into a resin solution so that they are completely wet.

Lay the wet fiberglass mat over your sculpture and press it into place, moulding it to the shape of the chicken wire framework. Ensure that the mat is smoothed out and fits snugly over the mould. Cover the entire sculpture with these mats, creating a uniform layer. Allow this first layer of fiberglass to dry for a few hours until it is hard but still slightly tacky.

Once the initial layer has cured, you can add another layer of resin and fiberglass mat. Make sure the subsequent layers adhere well to the previous ones. Continue this process, building up the thickness gradually, and allowing each layer to cure before adding the next. The number of layers will depend on your desired thickness, but typically, 3-8 layers of 1.5 oz chopped strand mat are sufficient.

If you want to enhance the strength of your mould, you can layer the mat between heavier weights of fiberglass cloth. Additionally, try to orient the fibres of the mat in different directions with each new layer. Fiberglass is strong across its axis but weak along its axis. By varying the orientation of the fibres, you can distribute the weak points along various axes, resulting in a much stronger mould.

Finally, finish your project by coating it with a gel coat or a smooth coat of resin. You can also paint it with polyurethane or alkyd enamel if desired.

Boiling Chicken Legs: The Secret to Perfect Barbecue

You may want to see also

Remove the mould and add final touches

When it comes to removing the mould and applying the final touches, attention to detail is key. The mould shapes the fibreglass into your custom design, and proper mould preparation is essential to avoid hours of frustrating clean-up later. A mould release agent is critical for ensuring the fibreglass separates smoothly from the mould. Evenly coat your mould with the release agent, paying special attention to crevices and edges.

After the curing process, it's time for demoulding, which gracefully unveils the form of your fibreglass creation. This stage demands patience, as it enriches the final creation with strength and durability. Once the fibreglass is demoulded, it's time for the finishing and detailing stage, where meticulous shaping, polishing, and adding intricate details elevate your creation. Use sandpaper or an electric sander to smooth rough edges and trim any excess fibreglass. Finishing coats and gel coats can also be applied to enhance the surface finish.

Quality control and testing are crucial to ensuring the longevity and performance of your fibreglass creation. This phase involves a meticulous examination to detect defects, followed by rigorous structural tests to ensure durability and strength. Visual and tactile assessments are important to identify any imperfections, air bubbles, cracks, or inconsistencies in the surface finish. Sanding with various grits of sandpaper and a powered orbital sander can help refine the shape and finish of your fibreglass body.

Finally, you can add the finishing touches that transform your fibreglass creation into a work of art. Paint the fibreglass to your desired colour and finish, allowing you to customise and showcase your creativity. Experiment with textures, patterns, and unique colour schemes to make your project stand out. Remember to always wear safety gear, such as gloves, goggles, and a respirator, when working with fibreglass to protect yourself from toxic fumes and fine particles.

The Ultimate Guide: Boosting Your Chicken Smoothie Trades

You may want to see also

Frequently asked questions

First, create your desired shape out of chicken wire, bending the wire and securing it in place so that it does not move during the fiberglass casting process.

Cover the chicken wire with aluminum foil, ensuring there are no gaps and that there are as few lumps as possible.

Spray the entire sculpture with a mold release agent, which will make it easier to remove the fiberglass later.

Cut your fiberglass mats to a manageable size, dip them in resin solution, and lay them over your sculpture. Press the mats into place, molding them to the shape of the chicken wire. Continue adding layers of mats and letting them dry until you achieve your desired thickness.